The 2004 Toyota Sienna Fuse Diagram Manual is a comprehensive guide providing detailed fuse box layouts, symbols, and safety tips for diagnosing electrical issues efficiently.

1.1 Importance of the Fuse Diagram Manual

The 2004 Toyota Sienna Fuse Diagram Manual is essential for identifying and resolving electrical system issues. It provides detailed layouts of fuse boxes, symbols, and safety guidelines, helping owners and technicians locate and replace fuses correctly. This manual ensures proper diagnosis and prevents potential damage to the vehicle’s electrical components, making it indispensable for maintenance and repairs.

1.2 Overview of the Toyota Sienna Fuse System

The 2004 Toyota Sienna features a fuse system designed to protect its electrical circuits from damage. Two main fuse boxes are located in the engine compartment and under the instrument panel. These housings contain fuses and relays that power various vehicle systems, such as lighting, accessories, and safety features. Proper understanding of this system is crucial for diagnosing and resolving electrical issues efficiently, ensuring optimal vehicle performance and safety.

Understanding the Fuse Box Locations

The 2004 Toyota Sienna has two main fuse boxes: one in the engine compartment and another under the instrument panel, crucial for electrical system diagnostics.

2.1 Fuse Box in the Engine Compartment

The engine compartment fuse box in the 2004 Toyota Sienna is located on the left side, housing essential fuses for systems like the headlights and charging system. This box is protected by a lid and contains high-current fuses that control critical vehicle functions. It is essential to refer to the fuse diagram for accurate identification and replacement of blown fuses to maintain proper electrical system operation.

2.2 Fuse Box Under the Instrument Panel

The fuse box under the instrument panel in the 2004 Toyota Sienna is located on the left side, behind a protective lid. This box controls various interior electrical systems, including the HVAC, radio, and lighting. Accessing it requires opening the lid, and it is protected to prevent accidental damage. Consulting the fuse diagram manual is essential for identifying the correct fuses and ensuring proper maintenance of these systems.

Reading the Fuse Diagram

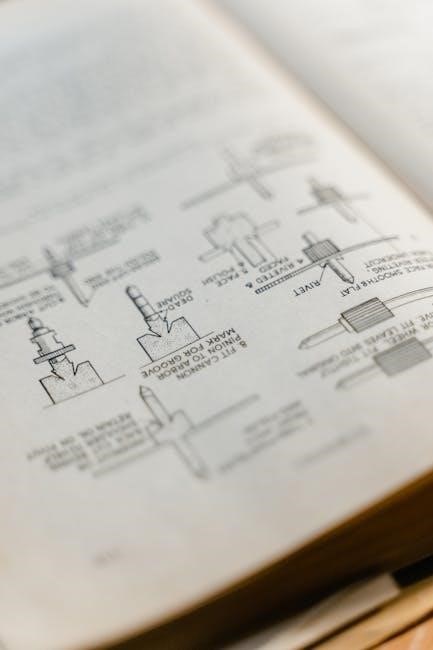

Reading the fuse diagram involves understanding symbols, abbreviations, and layouts to identify fuse functions and ratings accurately, ensuring proper diagnosis and repair of electrical systems.

3.1 Symbols and Abbreviations Used

The fuse diagram uses specific symbols and abbreviations to represent components like fuses, relays, and circuits. For example, “H-LP RL” denotes the right-hand headlight circuit, while “AM230” refers to the injection system. These symbols help identify fuse functions and locations quickly. Understanding these abbreviations is crucial for accurate troubleshooting and repairs. Always reference the manual or online forums for clarity on unfamiliar symbols to ensure safe and effective diagnoses.

3.2 Understanding Fuse Functions and Ratings

Fuses protect electrical circuits from overcurrent by breaking when excessive power flows. Each fuse has a specific rating (e.g., 5A to 30A) matching the circuit it safeguards. Higher-rated fuses handle more power, like those for power windows or rear AC. Lower-rated fuses protect sensitive systems, such as interior lights. Referencing the manual ensures correct fuse replacement, preventing damage or fire hazards. Always use the specified rating for safe operation.

Identifying and Replacing Blown Fuses

Locate the blown fuse using the diagram, remove it with a fuse puller, inspect for damage, and install a replacement with the correct rating to restore function.

4;1 Steps to Locate a Blown Fuse

Use the fuse diagram in the manual to identify fuse locations. Access the engine compartment and instrument panel fuse boxes. Visually inspect fuses for damage or discoloration. Remove suspicious fuses with a puller and test for continuity using a multimeter. This systematic approach helps pinpoint the faulty fuse without causing further electrical issues.

4.2 Safely Replacing a Fuse

Turn off the ignition and all electrical accessories. Locate the fuse box using the manual. Remove the blown fuse with the provided tool. Inspect and confirm the fuse is faulty using a multimeter. Install a replacement fuse of the correct amperage rating. Avoid over-tightening to prevent damage. Restore power and test the affected system to ensure proper function. Always follow safety precautions to prevent electrical shocks or system damage.

Common Fuse-Related Issues in the 2004 Toyota Sienna

Frequent blown fuses often indicate overloaded circuits or electrical system malfunctions. Common causes include faulty wiring, excessive current, or failing components. Troubleshooting is essential for resolution.

5.1 Frequently Blown Fuses and Their Causes

The 2004 Toyota Sienna often experiences blown fuses due to overloaded circuits or faulty components. Common culprits include the “TAIL” fuse for rear lights and “DOOR” fuse for power doors. Issues like short circuits, worn-out relays, or extreme temperatures can trigger these failures. Consulting the fuse diagram manual helps identify affected systems and prevents recurring problems by addressing root causes.

5.2 Troubleshooting Electrical System Problems

Troubleshooting electrical issues in the 2004 Toyota Sienna begins with consulting the fuse diagram manual to identify blown fuses. Check for short circuits, faulty relays, or corroded connections. Use a multimeter to test components like sensors and wiring. The manual provides step-by-step guidance to trace and resolve issues efficiently, ensuring safe and effective repairs without causing further damage.

Safety Precautions When Working with Fuses

When working with fuses, always disconnect the battery, use insulated tools, and avoid sudden movements. Ensure proper grounding and consult the manual for specific safety guidelines.

6.1 Essential Safety Tips

Always disconnect the battery before working with fuses to prevent electrical shocks. Use insulated tools to avoid short circuits. Ensure the vehicle is in park and apply the brake. Never touch electrical components with bare hands. Avoid sudden movements that may cause damage; Consult the manual for specific precautions and follow proper grounding procedures to ensure safety while diagnosing or replacing fuses in your 2004 Toyota Sienna.

6.2 Tools and Equipment Needed

Essential tools include insulated pliers, screwdrivers, and a multimeter for diagnosing electrical issues. A battery disconnect tool ensures power is off. Use a fuse puller to safely remove fuses without damage. Keep gloves and safety goggles on hand for protection. Ensure all tools are rated for automotive use to prevent damage or injury while working with the 2004 Toyota Sienna’s fuse system.

Step-by-Step Guide to Using the Fuse Diagram Manual

Refer to the index for fuse locations, cross-reference symbols with their meanings, and apply the instructions to diagnose and repair electrical issues efficiently using the manual.

7.1 Navigating the Manual

Navigate the manual by starting with the index to locate specific fuse diagrams. Use the symbols key to understand abbreviations and markings. Cross-reference fuse locations with the detailed illustrations provided. Identify the cigarette lighter fuse or power windows fuse by matching labels in the index. Refer to the wiring diagrams for complex systems like the A/C or radio. Troubleshooting sections help link symptoms to fuse issues, streamlining repairs. Always cross-check information to ensure accuracy.

7.2 Applying the Information to Repair

Use the fuse diagram to identify blown fuses by matching symptoms with the corresponding fuse functions. Cross-reference the fuse locations and ratings to ensure correct replacements. Follow safe replacement procedures, such as disconnecting the battery before swapping fuses. Refer to troubleshooting guides for complex electrical issues. Regularly inspect fuses to prevent recurring problems and consult additional resources if repairs are beyond your expertise.

Additional Resources for Further Assistance

Explore official Toyota service manuals, online forums, and wiring diagrams for in-depth guidance. Websites like fuse-box.info offer detailed fuse layouts and troubleshooting tips specific to the 2004 Sienna.

8.1 Official Toyota Service Manuals

The 2004 Toyota Sienna service manual provides a detailed guide to the vehicle’s electrical systems, including fuse diagrams, wiring charts, and repair procedures. It covers fuse box locations, circuit information, and troubleshooting steps. Available online, the manual is a valuable resource for understanding and maintaining the Sienna’s electrical components. It ensures accurate and safe repairs, making it indispensable for both DIY enthusiasts and professional technicians. Visit https://fuse-box.info for additional resources.

8.2 Online Forums and Communities

Online forums and communities, such as Toyota Nation or Sienna Forums, provide valuable insights and discussions about the 2004 Toyota Sienna’s electrical system. Members share experiences, troubleshooting tips, and solutions for common fuse-related issues. These platforms are ideal for DIY enthusiasts seeking advice or verification of repair steps. They often include detailed posts and images, making them a useful supplement to the official manual. Visit https://fuse-box.info for additional resources and guidance.

The 2004 Toyota Sienna Fuse Diagram Manual is an essential tool for understanding and maintaining your vehicle’s electrical system, ensuring safety and optimal performance always.

9.1 Summary of Key Points

The 2004 Toyota Sienna Fuse Diagram Manual provides a clear understanding of the vehicle’s electrical system, emphasizing fuse locations, symbols, and safety precautions. It guides users through diagnosing and replacing blown fuses, troubleshooting common issues, and utilizing official resources for further assistance. By following the manual, owners can maintain their Toyota Sienna’s optimal performance and ensure electrical system reliability.

9.2 Final Tips for Maintaining Your Toyota Sienna

Regularly inspect fuses to prevent electrical issues and ensure optimal performance. Always consult the manual before making repairs. Replace blown fuses with the correct rating to avoid damage. Avoid using makeshift repairs, as they can lead to further complications. Check the electrical system periodically for wear or damage. Refer to official Toyota resources for reliable guidance and maintenance advice.