The Hustler Super Z Parts Manual is a comprehensive guide essential for maintaining and repairing your mower. It provides detailed parts listings, diagrams, and ordering information to ensure accurate part replacement. Designed to help users identify and procure components efficiently, the manual emphasizes safety, troubleshooting, and proper maintenance practices. With clear instructions and model-specific details, it is an indispensable resource for owners and technicians alike, helping to maintain optimal performance and extend the lifespan of your equipment.

Overview of the Hustler Super Z

The Hustler Super Z is a high-performance zero-turn mower designed for professional landscaping and heavy-duty residential use. Known for its robust fabricated steel deck and durable one-piece steel frame, it offers unmatched strength and reliability. Equipped with powerful Kawasaki engines and a range of deck sizes (60, 66, 72 inches), it delivers efficient cutting and precision handling. Its innovative SmoothTrak steering system ensures smooth operation, while its high-speed capability makes it ideal for large areas, combining power, agility, and productivity.

Importance of the Parts Manual

The Hustler Super Z Parts Manual is crucial for maintaining and repairing your mower. It provides detailed diagrams, part numbers, and descriptions, ensuring accurate identification and ordering of components. This manual is essential for troubleshooting issues, performing routine maintenance, and extending the lifespan of your equipment. By following its guidelines, users can ensure safety, optimal performance, and cost-effective repairs, making it an indispensable resource for both owners and technicians.

Locating the Hustler Super Z Parts Manual

The Hustler Super Z Parts Manual can be easily found using the official Hustler Parts Lookup Feature or downloaded from authorized sources like Hustler Turf or trusted dealerships.

Official Hustler Parts Lookup Feature

The official Hustler Parts Lookup Feature is a user-friendly tool designed to help you quickly identify and locate parts for your Hustler Super Z. By entering your mower’s 6-digit model number, you can access detailed parts diagrams, lists, and descriptions. This feature ensures accuracy when ordering parts, reducing errors and saving time. It also provides direct links to purchase genuine Hustler components, ensuring compatibility and quality. Visit the Hustler Turf website to utilize this resource effectively.

Downloading the Manual from Authorized Sources

To ensure authenticity and accuracy, download the Hustler Super Z Parts Manual from authorized sources like the official Hustler Turf website or trusted retailers. Visit the Parts Lookup section, enter your mower’s model number, and access the manual in PDF format. This guarantees you receive the most up-to-date and genuine documentation. Avoid unauthorized sites to prevent downloading incorrect or incomplete information. Always verify the source to maintain the quality and reliability of your repair and maintenance efforts.

Understanding the Structure of the Manual

The Hustler Super Z Parts Manual is organized into clear sections, including parts listings, diagrams, and maintenance schedules, making it easy to navigate and locate specific information efficiently.

Navigation and Organization

The Hustler Super Z Parts Manual is meticulously organized to enhance user experience. It features clear sections, including detailed parts diagrams, alphabetical indexes, and model-specific breakdowns. Users can easily locate components through categorized listings, while visual aids like exploded diagrams simplify identification. The manual’s logical structure ensures quick access to information, making maintenance and repairs more efficient. This organization is designed to streamline workflows for both professionals and DIY enthusiasts.

Key Sections Included

The Hustler Super Z Parts Manual includes vital sections like engine components, mower deck parts, and hydraulic systems. Detailed diagrams and part numbers are provided for easy identification. Safety guidelines and maintenance schedules are also highlighted, ensuring proper upkeep. Additionally, troubleshooting tips and repair guidance are included, making it a complete resource for users to manage their equipment effectively and safely, covering all aspects of maintenance and repair.

Commonly Sought Parts

Commonly sought parts include mower blades, deck components, and drive systems. Hydraulic parts and belts are also frequently replaced, ensuring optimal performance and longevity of the equipment.

Mower Blades and Deck Components

Mower blades and deck components are vital for optimal cutting performance. High-quality blades ensure precise cutting, while spindles and pulleys maintain deck stability. Regular sharpening and inspection of these parts are crucial to prevent wear and tear. Replacing damaged or dull blades enhances cutting efficiency and extends equipment lifespan. Always refer to the manual for specific part numbers and maintenance guidelines to ensure proper functionality and safety of your Hustler Super Z mower.

Drive and Hydraulic Parts

Drive and hydraulic components are essential for the Hustler Super Z’s mobility and functionality. These parts include transmissions, pumps, motors, and hoses, ensuring smooth operation. Regular inspection of fluid levels, seals, and connections is vital to prevent leaks and system failure. Referencing the manual for part numbers and maintenance schedules helps maintain optimal performance and longevity of these critical systems, ensuring reliable operation and minimizing downtime for your mower.

Troubleshooting with the Manual

The manual provides detailed guidance for diagnosing and resolving common issues, such as blade malfunctions or hydraulic system problems. It offers step-by-step solutions to help users identify and address issues efficiently, ensuring optimal equipment performance and minimizing downtime. This section is crucial for maintaining the Hustler Super Z’s functionality and longevity.

Diagnosing Issues

The manual offers a systematic approach to identifying problems, such as blade malfunctions or hydraulic leaks. It provides detailed symptoms, diagrams, and repair steps, enabling users to pinpoint issues efficiently. By referencing part numbers and troubleshooting guides, owners can diagnose problems accurately, ensuring timely repairs and minimizing downtime. This section is crucial for maintaining the Hustler Super Z’s performance and longevity.

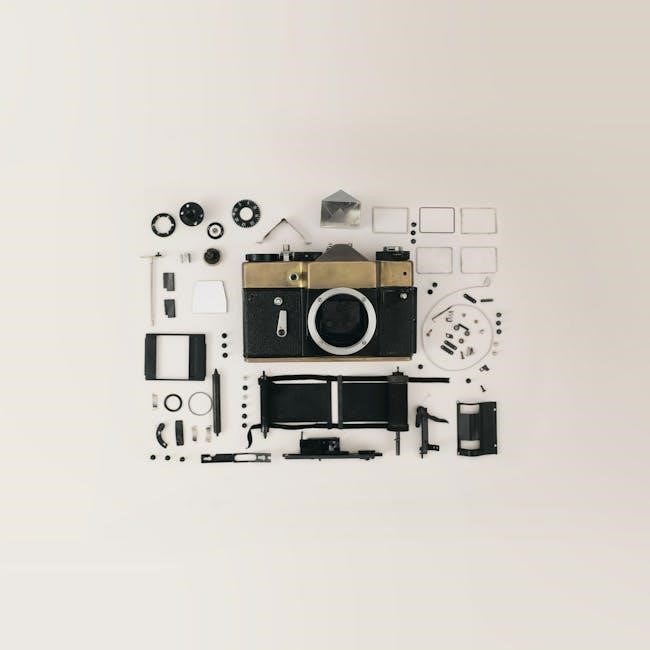

Repair Guidance

The manual provides step-by-step repair instructions for common issues, ensuring precise and effective fixes. Detailed diagrams and part numbers guide users through disassembly and reassembly. It emphasizes using authentic Hustler parts for reliability. Safety precautions and maintenance tips are included to prevent further damage. This section empowers users to address problems confidently, minimizing downtime and extending equipment lifespan.

Safety Guidelines and Precautions

The manual outlines essential safety practices, such as turning off blades when not in use and keeping shields in place. It emphasizes proper precautions to prevent accidents and ensure safe operation and maintenance of the Hustler Super Z.

Essential Safety Information

The Hustler Super Z Parts Manual emphasizes critical safety measures to ensure safe operation and maintenance. Always turn off the mower blades when not in use and keep all safety shields and covers securely in place. Regularly inspect the spark arrester and replace it every 500 hours or as needed. Adhere to these guidelines to prevent accidents and maintain a safe working environment while servicing or operating the equipment.

Preventive Measures

Regular maintenance is key to extending the life of your Hustler Super Z. Daily blade inspections ensure sharpness and prevent wear. Lubricate moving parts periodically to reduce friction and wear. Check and clean air filters to maintain proper engine performance. Follow the manual’s recommended maintenance schedule for routine services. Addressing minor issues early prevents major repairs later, ensuring your mower operates efficiently and reliably for years to come.

Maintenance Schedules

Regular maintenance ensures optimal performance and longevity of your Hustler Super Z. Follow the manual’s schedule for routine checks, lubrication, and part replacements to maintain efficiency and reliability.

Routine Checks and Services

Regular checks are vital for maintaining your Hustler Super Z. Inspect mower blades daily, sharpen or replace them as needed, and ensure proper blade alignment. Check oil levels, air filters, and hydraulic fluid regularly. Lubricate moving parts and inspect belts for wear. Clean the deck and underside to prevent debris buildup. Replace spark plugs and filters according to the manual’s schedule. These routine services help prevent issues, ensuring smooth operation and extending equipment lifespan.

Recommended Maintenance Intervals

Adhere to the Hustler Super Z Parts Manual for specific maintenance timelines. Oil changes are recommended every 100 hours, while air and hydraulic filters should be replaced every 200-300 hours. Sharpen mower blades monthly and inspect belts for wear every 50 hours. Hydraulic fluid levels should be checked weekly, and spark plugs replaced annually or as specified. Following these intervals ensures optimal performance, prevents wear, and extends the lifespan of your equipment.

Accessories for Enhanced Functionality

Bagger kits, mulch kits, and striping kits are popular accessories that enhance the Hustler Super Z functionality. These additions improve efficiency, versatility, and lawn aesthetics, ensuring professional results.

Available Accessories

The Hustler Super Z offers a range of accessories to enhance performance. These include high-quality belts, air filters, bearings, and hydraulic components. Additionally, specialty kits for mulching, bagging, and striping are available, allowing for customized mowing experiences. These accessories are designed to improve efficiency, durability, and overall functionality, ensuring your mower meets specific lawn care needs and maintains peak performance throughout its lifespan.

Installation Tips

When installing parts, always follow the guidelines in the Hustler Super Z Parts Manual. Ensure you use genuine Hustler parts for compatibility and reliability. Refer to the manual for specific torque specifications and alignment instructions. Properly secure all bolts and connectors to avoid loose components. Test the equipment after installation to ensure functionality. If unsure, consult a certified technician or Hustler dealer for professional assistance to guarantee safety and performance.

Understanding Part Numbers

Decoding part numbers is crucial for accurate ordering. The manual provides a structured system to identify components, ensuring compatibility and ease of procurement for maintenance and repairs.

Decoding Part Numbers

Part numbers in the Hustler Super Z Parts Manual follow a structured format for easy identification. Typically, they include a prefix, model-specific code, and suffix, ensuring precise component matching. Always use the exact part number listed in the manual when ordering to avoid errors. Providing the model and serial number to your parts representative further ensures accuracy. This system streamlines procurement and maintenance, preventing delays and ensuring compatibility. Bulk items like seals and hoses are sold by the foot for convenience.

Correct Ordering Practices

When ordering parts for the Hustler Super Z, always use the exact part number listed in the manual, not the index number. Provide the model and serial number to your parts representative for accuracy. Bulk items like seals and hoses are sold by the foot. Double-check the manual for any updates or changes before placing an order. This ensures compatibility and prevents errors, maintaining your equipment’s performance and longevity.

Comparing Hustler Super Z Models

The Hustler Super Z models vary in deck sizes, engine options, and features. Comparing them helps identify compatibility and ensures the correct parts are ordered for maintenance and repairs.

Differences Between Models

The Hustler Super Z models differ in deck sizes, engine options, and features. Deck sizes range from 60 to 72 inches, catering to various mowing needs. Engine choices include Kawasaki engines like the FX850V or FX1000V, offering varying horsepower. Each model may have unique components, such as advanced hydraulic systems for improved maneuverability. Additionally, some models come with optional features like mulch kits or baggers, enhancing functionality. Understanding these differences is crucial for selecting the correct parts for maintenance and repairs, ensuring compatibility and optimal performance. Always refer to the specific model’s parts manual for accurate information on components and accessories.

Selecting the Right Parts

Always use the exact part numbers from the Hustler Super Z Parts Manual to ensure compatibility. Verify the model and serial number before ordering to match your equipment. Bulk items like seals and hoses are sold by the foot, so specify quantities accurately. Use the Hustler Parts Lookup tool for precise searches. For authenticity, purchase from authorized dealers or directly through Hustler Turf to avoid counterfeit components.

The Hustler Super Z Parts Manual is a vital resource for maintaining and repairing your mower. It ensures efficiency, proper troubleshooting, and regular maintenance, maximizing performance and longevity. Always refer to it for accurate part identification and safe repair practices to keep your equipment running at its best.

The Hustler Super Z Parts Manual offers numerous advantages, including quick part identification, detailed diagrams, and clear maintenance schedules. It serves as a reliable reference for troubleshooting and repair, ensuring your equipment runs smoothly. By providing safety guidelines and preventive measures, it helps avoid costly damages. This manual is essential for professionals and DIYers alike, making it a valuable tool for maintaining and extending the life of your mower.

Final Tips for Users

Always refer to the Hustler Super Z Parts Manual for accurate part numbers and repair guidance. Use genuine Hustler parts for reliability. Regularly update your manual for the latest information. Keep the manual in an accessible location for quick reference. Follow safety guidelines to prevent accidents and ensure optimal performance. By adhering to these tips, you’ll maintain your equipment effectively and extend its lifespan. Stay informed and proactive with your maintenance routine.