Welcome to the Stealth Cam Deceptor Manual, your comprehensive guide to mastering the Deceptor trail camera. This manual provides detailed insights into setup, features, and functionality to ensure optimal performance and customization. Discover how to maximize camera capabilities, troubleshoot common issues, and unlock advanced settings for superior results in wildlife monitoring and surveillance.

1.1 Overview of the Stealth Cam Deceptor

The Stealth Cam Deceptor is a cutting-edge trail camera designed for remote surveillance and wildlife monitoring. Featuring cellular connectivity, high-resolution imaging, and advanced detection technology, it offers seamless functionality for capturing images and videos. Its robust design and user-friendly interface make it ideal for outdoor use, ensuring reliable performance in various environments.

1.2 Importance of the Manual for Proper Camera Functionality

The manual is essential for understanding and optimizing the Stealth Cam Deceptor’s performance. It guides users through setup, configuration, and troubleshooting, ensuring all features are utilized effectively. Proper functionality relies on following the manual’s instructions, which help users avoid common issues and maximize the camera’s capabilities for reliable and efficient operation in the field.

Key Features of the Stealth Cam Deceptor

The Stealth Cam Deceptor offers advanced cellular connectivity, high-quality image and video capture, and robust triggering technology. It also features multi-zone coverage and is powered by the Stealth Cam Command app for remote control and on-demand functionality, ensuring reliable performance in various surveillance scenarios.

2.1 Cellular Connectivity and Remote Monitoring

The Stealth Cam Deceptor excels with its advanced cellular connectivity, enabling remote monitoring through the Stealth Cam Command app. It supports dual-network functionality, automatically connecting to the strongest signal for reliable performance. Users can access real-time updates, adjust settings, and receive notifications, ensuring seamless surveillance and control from anywhere. This feature enhances convenience and efficiency for wildlife monitoring and security applications.

2.2 High-Quality Image and Video Capture

The Stealth Cam Deceptor delivers exceptional image and video quality with its advanced CAM technology. It captures crisp, high-resolution photos and videos, even in low-light conditions, thanks to its superior night vision capabilities. Users can customize settings to optimize image quality, ensuring vivid and detailed visuals for wildlife monitoring or surveillance purposes, making it a reliable choice for outdoor use.

2.3 Advanced Triggering and Detection Technology

The Stealth Cam Deceptor features cutting-edge triggering and detection technology, offering fast and accurate motion detection. Its advanced PIR sensor covers multiple zones of angle and distance, minimizing false triggers and ensuring precise capture. Adjustable sensitivity settings allow users to customize detection based on their environment, making it ideal for wildlife monitoring and security applications.

Setting Up the Stealth Cam Deceptor

Setting up your Stealth Cam Deceptor involves installing the battery and SIM card, configuring settings, and connecting to the Stealth Cam Command app for remote monitoring. Follow the manual’s guidance to ensure proper installation and connectivity for optimal performance.

3.1 Initial Camera Setup and Configuration

Begin by installing the battery and SIM card, then access the camera’s settings through the Stealth Cam Command app. Create an account, scan the QR code under the battery tray, and follow in-app instructions to configure network settings and ensure proper connectivity for remote monitoring and functionality.

3.2 Installing the Battery and SIM Card

Insert the SIM card into the designated slot, ensuring the gold contacts face downward. Next, install the battery by aligning it with the compartment’s guides. Close the compartment securely and power on the camera. Finally, test connectivity by following the in-app instructions to ensure proper network functionality and remote access.

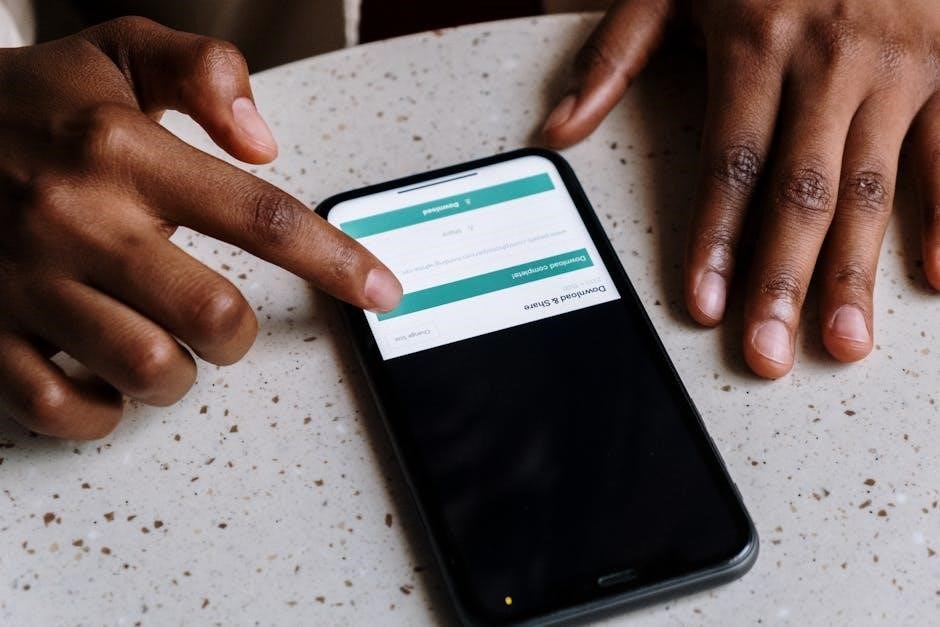

3.4 Connecting the Camera to the Stealth Cam Command App

Download and install the Stealth Cam Command app, then create an account or log in. Tap “Add Device” and locate the QR code under the camera’s battery tray. Scan the QR code using your smartphone to connect the camera to the app. Follow in-app instructions to complete the setup and ensure remote functionality.

Camera Functionality and Modes

The Stealth Cam Deceptor offers versatile modes, including motion detection, day/night vision, and customizable video/photo capture settings, ensuring optimal performance for wildlife monitoring and surveillance needs.

4.1 Motion Detection and Capture Modes

The Stealth Cam Deceptor features advanced motion detection, capturing images or videos upon sensing movement. Multiple zones ensure accurate triggering, while burst and time-lapse modes enhance flexibility. The camera’s PIR technology minimizes false triggers, and adjustable sensitivity settings allow customization for varying environments and wildlife monitoring needs.

4.2 Day and Night Vision Capabilities

The Stealth Cam Deceptor excels in both day and night vision, capturing full-color images during daylight and clear black-and-white photos at night using IR LEDs. The camera’s invisible flash ensures stealthy operation, while adaptive sensors optimize image quality in varying light conditions, enabling round-the-clock monitoring with reliable results.

4.3 Video and Photo Capture Settings

The Stealth Cam Deceptor offers customizable video and photo settings to suit your needs. Adjust resolution up to 4K for videos and select from multiple megapixel options for photos. Enable burst mode for rapid photo capture or set time-lapse intervals for continuous monitoring. These settings ensure flexibility in capturing the perfect shot for wildlife or surveillance purposes.

Customizing Camera Settings

Customize your Deceptor camera with adjustable trigger sensitivity, PIR settings, and time-lapse features for tailored performance in various environments, ensuring optimal results.

5.1 Adjusting Trigger Sensitivity

Adjusting the trigger sensitivity on your Stealth Cam Deceptor allows you to fine-tune motion detection accuracy. Access the setting via the camera menu, selecting from low to high sensitivity levels. Higher sensitivity captures more motion, while lower settings reduce false triggers. Experiment with different levels to optimize detection for your specific environment and target activity patterns effectively.

5.2 Configuring PIR Sensitivity and Delay

Configuring the PIR (Passive Infrared) sensitivity and delay on your Stealth Cam Deceptor fine-tunes motion detection. Adjust sensitivity levels to detect movement accurately, and set delay intervals between triggers to avoid excessive captures. Use the camera menu to customize these settings, optimizing detection for wildlife or surveillance needs while minimizing false triggers and conserving storage and battery life efficiently.

5.3 Setting Up Time Lapse and Multi-Shot Features

Configure the Time Lapse feature to capture images at set intervals, ideal for monitoring long-term activity. The Multi-Shot mode takes bursts of photos with one trigger, ensuring comprehensive coverage of movement. Use the camera menu or app to customize these settings, adjusting intervals and burst counts to suit your surveillance or wildlife monitoring needs for efficient and detailed image capture.

Using the Stealth Cam Command App

The Stealth Cam Command App allows remote camera management, offering live viewing, settings customization, and notifications. It streamlines monitoring and enhances your surveillance experience effectively.

6.1 App Features and Remote Camera Control

The Stealth Cam Command App offers robust features for remote camera control, including live viewing, custom settings, and real-time notifications. Users can adjust camera settings, monitor activity, and receive alerts directly on their devices, ensuring seamless surveillance and efficient management of the Deceptor camera from anywhere.

6.2 Receiving Notifications and Managing Data Plans

The Stealth Cam Command App enables users to receive real-time notifications for detected events, ensuring prompt awareness of camera activity. You can customize notification preferences and monitor data usage to manage plans effectively, preventing overage. This feature ensures efficient surveillance while maintaining control over cellular data consumption, optimizing your camera’s performance and cost-effectiveness;

6.3 Updating Firmware for Enhanced Performance

Regularly updating the Stealth Cam Deceptor firmware ensures optimal functionality and performance. Use the Stealth Cam Command App to check for and install the latest updates. Firmware updates enhance camera features, improve connectivity, and fix issues. Follow in-app instructions to complete the update process, ensuring your camera operates at its best with the latest advancements.

Troubleshooting Common Issues

Troubleshoot connectivity, sensor, and battery issues with the Stealth Cam Deceptor. Consult the manual or contact support for resolving malfunctions and optimizing performance effectively.

7.1 Resolving Connectivity and Network Problems

Experience issues with cellular connectivity? Restart the Stealth Cam Deceptor and ensure the SIM card is properly installed. Check network signal strength and verify data plan status. Use the Stealth Cam Command app to test connections and configure settings. If problems persist, contact support for further assistance or firmware updates.

7.2 Addressing Sensor Malfunctions and False Triggers

Experiencing sensor issues or false triggers? Adjust the PIR sensitivity and trigger delay settings via the Stealth Cam Command app. Ensure the camera lens and sensors are clean. Check for obstructions and test in a controlled environment. If malfunctions persist, reset the camera or update firmware for optimal performance and accuracy.

7.3 Solving Battery Life and Power Issues

Ensure your Stealth Cam Deceptor operates at peak efficiency by checking battery levels via the app. Adjust power-saving settings and reduce unnecessary features. Clean battery contacts and verify proper installation. If issues persist, update firmware or reset the camera. Always use high-quality batteries suitable for outdoor conditions to maximize performance and longevity in the field.

Best Practices for Optimal Camera Use

For optimal performance, position the camera strategically, configure settings according to your needs, and regularly update firmware to ensure reliability and security in various environments.

8.1 Strategic Placement for Maximum Coverage

Position the Stealth Cam Deceptor at optimal heights and angles to cover key areas like trails or food sources. Ensure the camera faces north to avoid direct sunlight and minimize false triggers. Use the environment to camouflage the device and test connectivity via the Stealth Cam Command app for reliable performance.

8.2 Maintenance Tips for Long-Term Reliability

Regularly clean the camera lens and housing to prevent dirt buildup. Update firmware via the Stealth Cam Command app for optimal performance. Check battery levels and replace or charge as needed. Inspect sensors and connections to ensure reliability. Test camera connectivity periodically to maintain seamless operation and capture high-quality images consistently.

8.3 Ensuring Data Security and Privacy

Protect your camera data by using strong passwords and enabling encryption. Regularly update firmware to ensure security patches are applied. Avoid sharing sensitive camera locations or login details. Use secure networks when accessing the Stealth Cam Command app to prevent unauthorized access. Always log out after remote sessions for added privacy protection.

The Stealth Cam Deceptor Manual equips users with essential knowledge to optimize their camera experience. By following the guide, users can maximize functionality, troubleshoot effectively, and ensure privacy. Explore advanced features, maintain security, and leverage the camera’s full potential for wildlife monitoring, surveillance, or outdoor adventures with confidence.

9.1 Summary of Key Features and Benefits

The Stealth Cam Deceptor offers advanced cellular connectivity, high-quality image capture, and robust detection technology. Its motion sensors, day/night vision, and customizable settings ensure efficient monitoring. The camera’s remote access via the app enhances user control, while features like time-lapse and multi-shot modes provide versatile capture options. These capabilities make it an excellent choice for wildlife surveillance and outdoor security.

9.2 Encouragement for Effective Camera Utilization

Leverage the Stealth Cam Deceptor’s cutting-edge technology to enhance your wildlife monitoring and security efforts. Explore its customizable settings, remote access, and high-quality imaging to capture every moment. By following the manual’s guidance, you can optimize performance and maximize the camera’s potential for reliable, efficient, and superior results in any environment or condition.